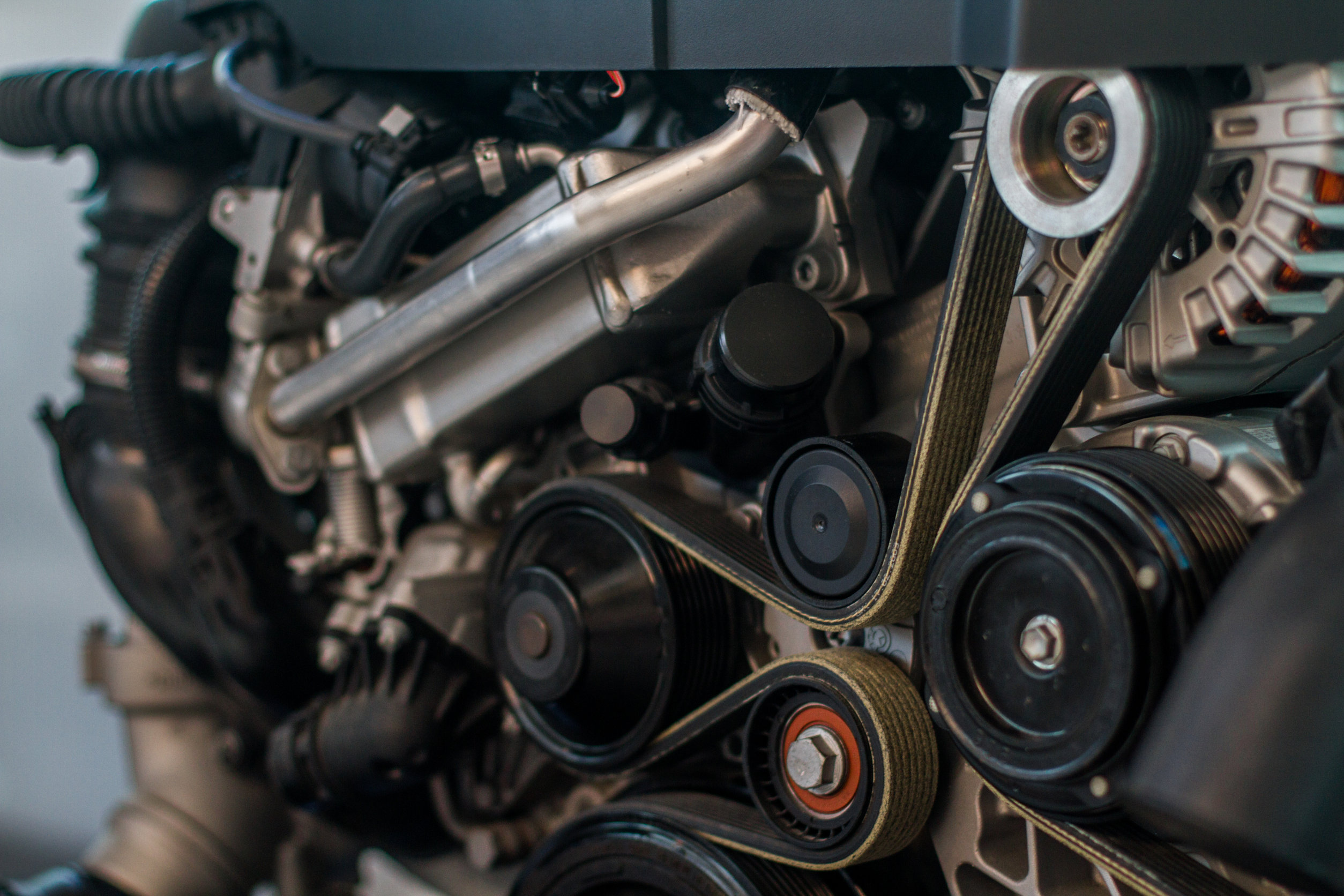

When modern automobile designers moved away from having independent belts running all the accessories and engine bay, replacing that with a serpentine belt design, it was seen as a major leap forward.

But while there are some significant advantages to having all of your accessories run off of a singular belt (especially when it is properly maintained), a lot of trouble can bubble up with this single point of failure.

Anyone that has had a serpentine belt pop off understands exactly what we are talking about.

Worst of all, with so many different points of contact with this serpentine belt a number of things can cause it to become dislodged – sometimes one right after another.

You might find yourself troubleshooting why your serpentine belt pops off every couple of months, even, especially if the root cause is a separate accessory than the last time.

Luckily, though, figuring out exactly what’s happening under the hood – and remedying your serpentine belt popping off – is generally a pretty simple and straightforward process.

Here’s what you need to know to fix this problem going forward.

Why Does My Serpentine Belt Keep Coming Off?

As we highlighted a moment ago, your serpentine belt is a singular point of failure in your engine bay because it is connected to so many different accessories.

At the same time, each of those individual accessories (and the pulleys that they are connected to) can represent different points of failure for the serpentine belt itself.

Most of the time, though, your serpentine belt is going to come dislodged because of three core reasons:

- There’s something wrong with the belt tensioner itself

- There’s a misalignment with an accessory pulley or

- There’s a defective bearing somewhere along the belt system

Faulty Belt Tensioner

The serpentine belt has an independent tensioner module that works to keep even pressure on the serpentine belt across all of the individual pulleys while it is in motion.

This tensioner module can be moved back and forth to replace or repair the serpentine belt as necessary.

When it is fully engaged it applies the maximum amount of tension. When it is disengaged, though, it’s almost like the serpentine belt has nothing holding it in place at all.

During normal operation, that full engagement is going to keep your serpentine belt on the track at all times. If something happens to the tensioner system, though, your belt is going to come loose – and maybe even fly off completely – faster than you would have thought possible.

Not Enough or Too Much Tension on the Belt

Another common problem that might be causing trouble for your serpentine belt – to the point where it starts popping off – is if there’s not enough tension on the belt itself during normal operations (or even too much tension).

Like we just mentioned a moment ago, the tensioner system is responsible for maintaining just the right amount of pressure on the serpentine belt against all of the individual pulleys it runs.

If the tensioner is to loose (or if the belt itself is to lose), it isn’t going to be held in place. As soon as everything starts spinning up and into action the belt is going to come flying off.

We’re not talking about a belt that is tremendously loose here, either.

You might have a belt that’s only a few millimeters loose on a serpentine installation and it is still going to come flying off the very first chance it gets.

Too much tension can cause problems as well.

All that extra attention is going to stretch the serpentine belt beyond its normal capabilities. That might be all right at first (and your accessories might even work the way they were intended to initially), but as soon as you stop your vehicle and the belt has time to relax it’s going to end up to loose all over again.

The next time that you fire your vehicle up that belt is going to want to spend right off of its position!

Bad Bearings

Bearings that have gone bad (bearings on the alternator, power steering, or water pump pulley in particular) can throw your belt off as well.

These bearings are necessary for keeping your serpentine belt running smoothly but also responsible for keeping it running in the right direction.

If the bearings have flat spots on them, cracks, or are getting gummed up they aren’t going to operate as smoothly as they would have normally.

All that extra vibration is going to find its way right into your serpentine belt – and you run the risk of vibrating your belt right out of position.

You probably won’t break your belt like this, but you are definitely going to throw it off of alignment – and that’s going to cause all kinds of trouble for you (not just immediately, but later down the line as well).

What Kind of Things Should I Be Looking for to Diagnose the Problem?

Thankfully, there are some pretty obvious signs and symptoms of your serpentine belt getting ready to be thrown out of position that you should be on the lookout for.

We are talking about things like:

- Odd squeaking and grinding noises that are coming out of your engine bay

- Odd or unusual wear and tear on your serpentine belt when you inspected

- Failure with your belt driven accessories, an obvious sign that the belt isn’t operating the way it should

- A lot of wear on the pulley system and the bearings themselves

- A lot of “bleeding” rust or obvious signs of cracks on the serpentine belt, showing signs of compromise

Obviously, it’s important to keep an eye on your serpentine belt whenever you do regular maintenance on your vehicle just to see that everything is running smoothly.

It might not be a bad idea to fire up your vehicle and let it idle in your driveway for a couple of minutes every month or so with the hood popped.

You’ll be able to see that your serpentine belt is operating the way it should. You’ll also be able to spot any major problems early, fixing them before they become catastrophic failures.